Branding Solutions

IN A WORLD WHERE FIRST IMPRESSIONS MATTER MOST, MAKE YOURS UNFORGETTABLE!

Choose from 12 different branding solutions.

What is Embroidery?

A design stitched onto a material using a high-speed, computer-controlled sewing machine. Embroidery is commonly used on logo patches, apparel, caps or hats.

Advantages:

- Prestigious look.

- Cost-effective for small quantities.

- Durable - won't fade or wash away.

What is DTF?

DTF (Direct to Film) branding is a

cutting-edge printing technique that transfers vibrant, high-resolution designs

onto fabric and other materials with precision.

Advantages:

- Detailed prints with vibrant colors.

- Ideal for apparel & promotional items.

- Perfect for fine details.

- Prints near seams for durability.

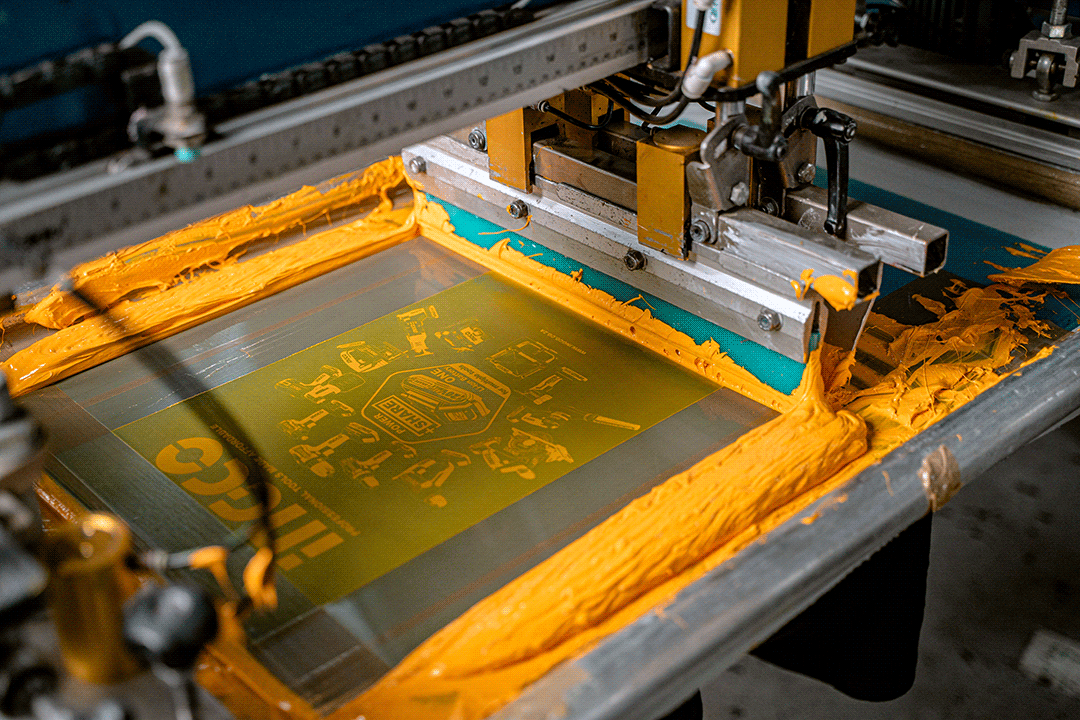

What is Screen Printing?

Screen printing is a traditional technique that uses a screen to apply ink onto a surface, creating a design or image. Separate screens are used for each colour, allowing for mass production of identical graphics.

Advantages:

- Ideal for large orders & cost efficient.

- Large branding area (up to A3)

- Good turnaround time.

- Suitable for small text & fine details.

- Half-tone printing available.

What is Heat Press?

A heat press is a machine that applies heat and pressure to imprint designs onto substrates like t-shirts. This process permanently applies heat transfers, resulting in long-lasting, high-quality prints.

Advantages:

- Brands up to A3 size.

- Quick turnaround time

- Captures small text & fine details.

- Supports shading (some limitations).

What is Sublimation?

Dye Sublimation transfers printed artwork onto substrates using a digital heat process. With sublimation you can customize garments (golfers, soccer jerseys, netball uniforms, and even rugby socks) for various events and sports.

Advantages:

- Long-lasting prints.

- Customise text & graphics.

- Unlimited colour options.

- Design from scratch, your way.

What is Digital Direct?

Digital Direct Printing is a process where a digital print is applied to transfer paper, then transferred onto a chemically-treated product, resulting in a durable, ink-based finish.

Advantages:

- Seamless prints, no trapping needed.

- Exceptional print quality.

- Cost-effective.

- Ideal for small to medium orders.

- Flexible with multiple design versions.

- Quick turnaround times.

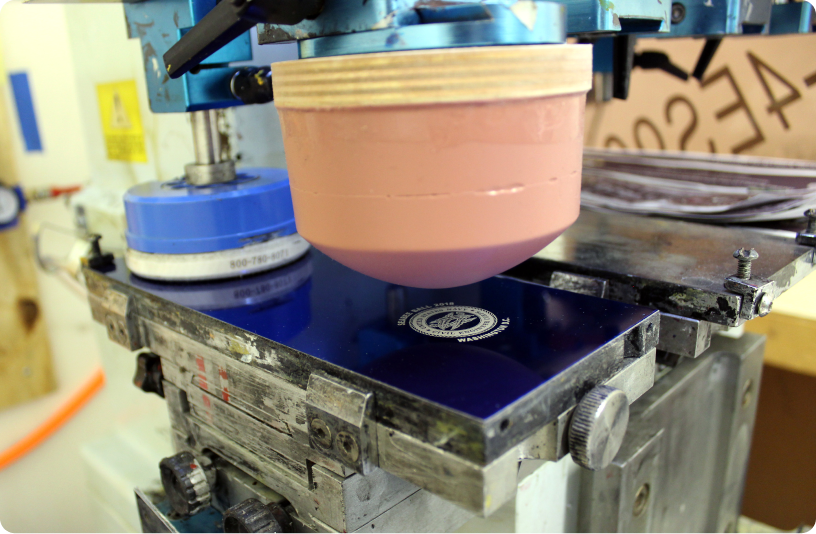

What is Pad Printing?

Ink is applied to an etched plate, then carefully wiped away, leaving ink only in the recessed areas. A silicone pad is pressed onto the plate, lifting the ink and transferring it precisely onto the product. This versatile technique is ideal for customizing promotional gifts.

Advantages:

- Can brand uneven/rounded surfaces.

- Quick turn-around time.

- High precision for details.

- Excellent image quality.

- Customizable designs and colors.

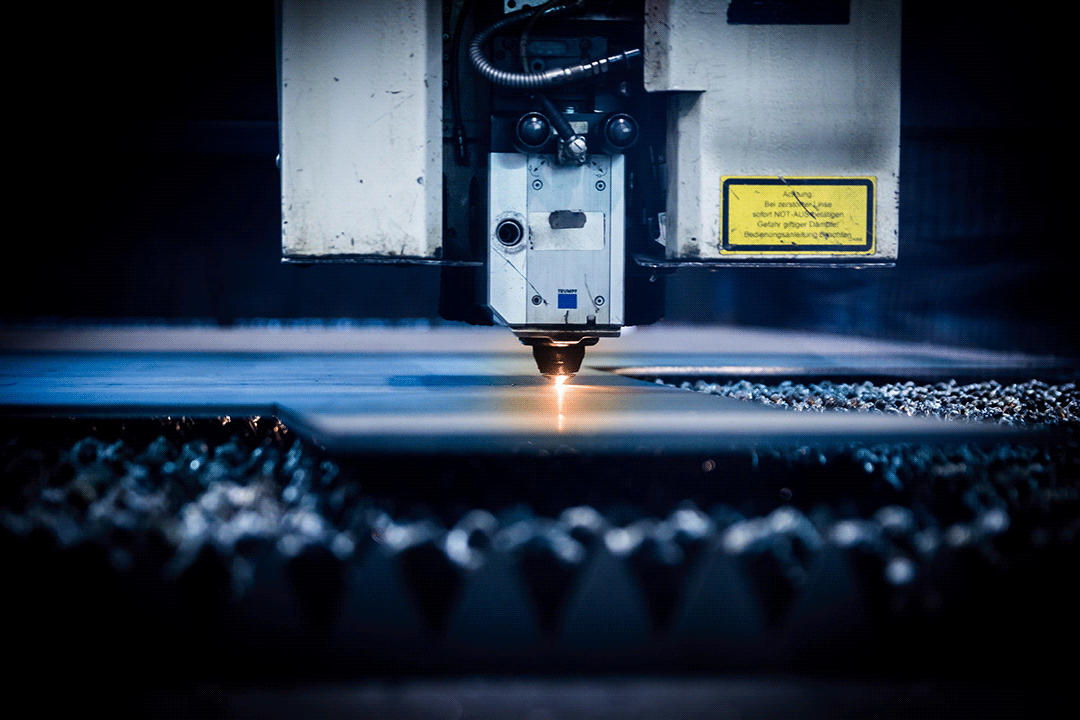

What is Laser Engraving?

Laser Engraving is a permanent marking process using a high-intensity light source. There are two main types of lasers: CO2 lasers are used for organic materials such as wood, glass, plastic, and leather, while YAG lasers are used for metals. This technique is commonly used for customizing gifts.

Advantages:

- Can brand all metal items (Yag laser).

- Decent turn-around time.

- Permanent, non-fading mark.

- Precise and detailed engravings.

What are Digital Stickers?

Stickers are digitally printed and precision-cut to shape. They are then carefully applied to the products. Digital stickers can be easily applied to both smooth and textured surfaces.

Advantages:

- Environmentally friendly.

- High print quality with vibrant colors.

- Low printing minimums for flexibility.

- Easy to remove without residue.

What is Doming?

A thin layer of Polyurethane resin is applied to a digital sticker, producing a raised 3D effect. Popular standalone products include dome stickers, custom name badges, keychains, and zip pulls.

Advantages:

- Can brand any smooth, flat surface.

- Full-colour print for vibrant visuals.

- Provides a high-quality finish.

- Highly scratch-resistant and durable.

What is Foiling?

Metallic foil is heat pressed onto surfaces using a heated metal block in a specialized machine. The foil is applied with heat, pressure, and precise timing. Foiling is often used to enhance Gifting Products.

Advantages:

- Luxurious gloss finish.

- Looks classy and sophisticated.

- Highly durable and resistant to fading.

- Adds a premium feel to products.

What is Debossing?

Debossing involves heat-pressing a custom metal die into a product's surface, creating a subtle, permanent impression. This process produces a sleek, professional finish that adds sophistication to various products.

Advantages:

- Creates a subtle, classy 3D look.

- Adds tactile depth to products.

- Long-lasting and durable.

- Boosts brand recognition.